What is a curved jaw coupling?

What is a curved jaw spider coupling and why is it superior?

Many engineers are familiar with jaw spider style couplings for their many benefits. They offer a wide range of operating temperatures, electrical isolation (if gap dimensions are observed), are fail-safe, provide easy installation and inspection, are maintenance free (no lubrication required), and are considered low-cost compared to other coupling styles.

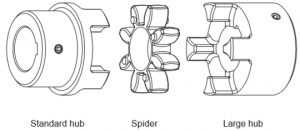

A traditional jaw spider coupling has trapezoidal jaws on the hub and rectangular teeth of the spider. An improvement to the traditional jaw spider coupling is the curved jaw spider coupling (see below). Curve jaw spider couples use concave jaws that contact with the convex teeth of the spider. The geometry of the curved jaw design leads to many benefits.

Benefits of curved jaw spider couplings

- Greater torque density – More surface contact between the spider teeth and hub jaws lead to greater torque transmission compared to an equivalent outside diameter of square jaw spider coupling.

- Vibration reduction – The greater surface contact between the spider teeth and hub jaws also lead to greater vibration dampening.

- Less stock required – The higher torque range for a given size leads to a reduction in stock investment and fewer part numbers to manage.

- Longer life, less maintenance – A curved spider compresses and returns to shape under torque which leads to better shock absorption and avoids edge stress which leads to a longer life spider and less downtime.

- Optional zero backlash – By using a pre-loaded spider, zero-backlash can be achieved in bi-directional applications.

Thank you for reading. We at Technical Partners Group are passionate about industry news and strive to educate about new products and technologies.

Visit KTR to learn more about couplings.

See all of our coupling products.