Collaborative Robot Safety Modes

What are robot collaborative safety modes and how do they affect production?

There are several different types of collaborative operations for robot as defined by the Robotic Industries Association (RIA). They are Safety-Rated Monitored Stop (SRMS), Hand Guiding, Speed and Separation Monitoring (SSM), and Power and Force Limiting (PFL). One or more of these methods are used in the operation of collaborative robots. Detailed descriptions of these collaborative operations can be found under RIA TR R15.606-2016 Section 5.5 (ISO/TS 15066.2016).

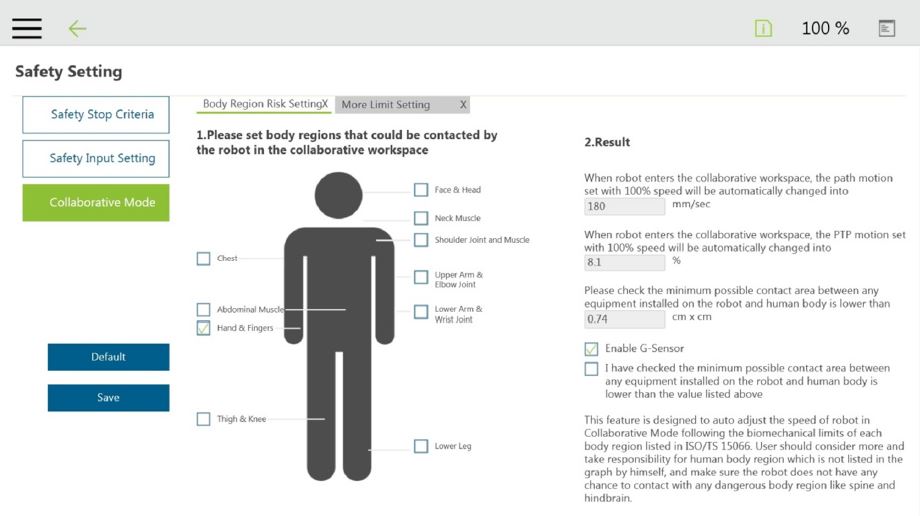

A collaborative robot is specifically designed for direct interaction with a human withing a defined workspace using one or more of the safety methods mentioned above. If an operator is within a collaborative workspace the robot’s movement is limited to speeds and forces that are not harmful to an operator or in some cases no movement is allowed. The speeds and forces a robot is allowed to move are defined by a safety assessment*. Factors such as load, speed, and the potential human contact location are all considered when determining the operating parameters of a robot in collaborative mode. A robot that does not implement any of the safety methods is considered a traditional robot and hard guarding is required and no human contact is allowed.

Limiting speed is essential when implementing a robot in a collaborative workspace to protect the human co-worker. If a robot needs to move at full speed then most often a traditional industrial robot is used along with the expensive hard guarding and the robot will no longer be considered collaborative. Unfortunately limiting a robot’s speed greatly reduces its production potential. The most capable collaborative robots have a feature that allows them to operate at full speed (near traditional robot speeds) and then when a collaborative safety input is triggered (often by a safety scanner) the robot will transition into a collaborative mode. This allows a cobot to offer the best of both worlds by increasing production when a co-worker is not present and safely operate next to them when they are.

*It is important when evaluating a collaborative robot to conduct a safety assessment. This can be accomplished by qualified in-house personnel or a contracted 3rd part.